CHAPTER 3

OWNERSHIP AND OPERATING HISTORY

3.1

Owners

The vessel was delivered to Rederiaktiebolaget Sally on 29 June 1980 under the name VIKING SALLY and placed in daily operation between Turku and Mariehamn in Finland, and Stockholm.

Rederiaktiebolaget Sally, based in Mariehamn, was at that time one of the major Finnish shipping companies with engagement in tankers and passenger vessels. The company was one of three which together formed the marketing consortium 'Viking Line' for ferry operations between Finland and Sweden (see Subchapter 2.1).

In 1986, ownership of the vessel was taken over by the Finnish/Swedish group Effjohn, owners of the competing Silja Line. The vessel continued, however, to operate in the Viking fleet under the original name. The technical operation was subcontracted with the remaining part of the Sally company.

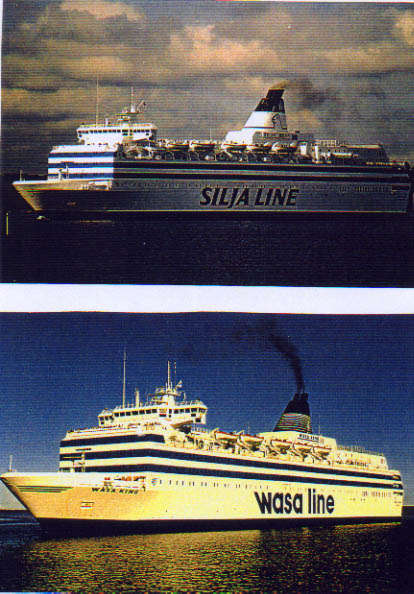

In April 1990 the Effjohn group took over full operation of the vessel and transferred her to Silja Line under the name SILJA STAR for continued operation between Turku and Stockholm.

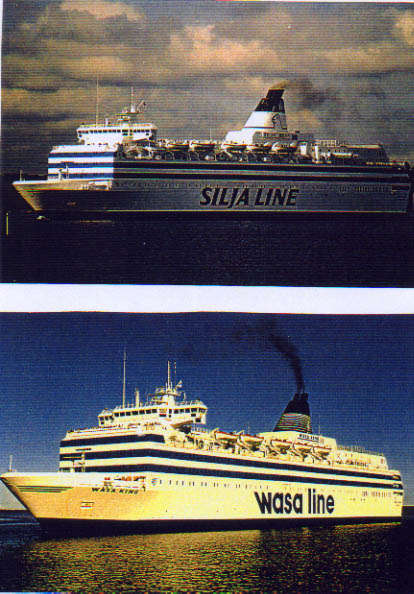

In January 1991 the vessel was transferred to the Wasa Line, another subsidiary of the Effjohn group, and was placed in the Wasa Line operation in the Gulf of Bothnia between Vaasa in Finland and Umeå and Sundsvall in Sweden. The ship was then renamed WASA KING. She operated on this route until she was sold to the Estline Marine Company Limited, which is registered in Cyprus.

The ship was under Finnish supervision and flew the Finnish flag from delivery until 14 January 1993.

3.2.1

Trade and crew

After commissioning, the vessel was placed into a rather tight schedule between Turku - Mariehamn - Stockholm, for example the vessel was operated for the first 10 years as follows:

| arrival | Stockholm | 07.00 hours | (stern ramps) |

| departure | Stockholm | 08.15 hours | |

| arrival | Mariehamn | 14.20 hours | (depending on car situation either bow or stern ramps) |

| departure | Mariehamn | 14.30 hours | |

| arrival | Turku | 18.30 hours | (bow ramp) |

| departure | Turku | 21.30 hours |

This schedule was only interrupted by stays at the yard, maximum once a year, and during winter time when the vessel stayed one Monday at Turku and the following Monday at Stockholm. These were the only times for maintenance work to be carried out in port, otherwise workers of the Sally owned shipyard in Mariehamn travelled with the vessel and carried out the necessary repairs at sea.

The vessel had two experienced crews consisting mainly of Ålanders having spent their working life on board of car/passenger ferries in the Baltic. The crews relieved each other every 14 days.

The route of VIKING SALLY led through the archipelagos off the Finnish west coast via the Åland Islands crossing 28 nm of open sea to Stockholm, i.e. the vessel was never more than 14 nm from the nearest land.

The two masters basically employed on VIKING SALLY during the time before she was sold were Lars Mäkki (still with Viking Line) and Håkan Karlsson - member of this 'Group of Experts' until his death in March 1997 - whilst Stig Lindström was her chief officer for many years (who passed away in January 1996). Lars Karlsson, the co-ordinator of the owners' newbuilding supervision team at Papenburg, was her first chief engineer and stayed on board in that capacity until 30.03.92, i.e. 91/2 months before she was sold to Estline Marine Company Limited.

The technical superintendent from the time of newbuilding until 1988 was Yngve Röblom, thereafter it was his colleague Lars Janlöv until SILJA STAR became WASA KING, at which time Charles Richardson became responsible for technical matters until she was handed over to Estline Marine Company Limited in mid January 1993.

According to the statements of these three technical superintendents they never had any problems with the vessel.

In the course of this investigation a number of people who had spent a great deal of time on board of or with the vessel have been interviewed by this 'Group of Experts', among others:

| Superintendent | Yngve Röblom |

| Superintendent | Lars Janlöv |

| Superintendent | Charles Richardson |

| Captain | Lars Mäkki |

| Chief officer | Stig Lindström |

| Chief engineer | Lars Karlsson |

| 1st Engineer | Karl Mattson |

| Electrician | Dag Märtensson |

| Electrician | Per Erik Söderlund |

| Boatswain | Juhani Luttunen |

| Motorman | Göran Lindström |

| Repair manager of Turku Shipyard | Ari Puroya |

The information obtained on the operation of the vessel is summarised as follows:

- Also at sea the vessel was run all the time on a very tight schedule, i.e. with all 4 main engines constantly at 90% output, unless weather conditions commanded reduction.

- In the engine control room (ECR) there were two output regulators for the main engines which were normally set at 90%. The output of the propulsion plant could be changed from the ECR. The propulsion plant could be run on "Combinator" or on "Constant Revolutions". Except during yard trials in 1980 the "Combinator" mode was always used. Up to 70% output pitch and revolutions were increasing simultaneously until the maximum revolutions were reached. Thereafter the output could be further increased by increasing the pitch while the revolutions remained unchanged.

- It has to be remembered that VIKING SALLY was originally built for traffic within the archipelago. When trading in the open Baltic in heavy seas a tendency of the visor to move sideways was observed which was created by the recess in the shell plating aft of the visor and caused the bow to set-in very heavily. When the vessel was, however, proceeding against head seas the pressure on the visor was in the aft direction. (Force direction is aft.)

- Reduction of speed in heavy head seas is not only a question of reduction of stress on vessel's and visor's structure and fixing points, but also the comfort of passengers has to be taken into account. Lars Karlsson made at least 1000 cruises and more than 100 times reduced the engine output himself in the engine room when he considered it necessary in heavy weather. He did so for the last times in July 1991 when the vessel was already sailing as WASA KING between Vaasa and Umeå/Sundsvall and consequently the vessel arrived once 11/2 hours late and another time 21/2 hours late.

- When the vessel was sailing between Turku and Stockholm there had to be two officers and one AB on the bridge. When she was shifted to the Vaasa/Umeå trade the owners wanted to spare one officer, which was accepted by F.B.N. under the condition that the control panel for the indicator lights for visor and bow ramp were moved to the large operation panel in front of the bridge where the lights could be seen from the seats of master and watch-officer. This was done some time in 1991.

- On the car deck 4 cameras were installed prior to delivery in 1980, i.e. one forward towards the forward ramp, two at the sides and one looking aft towards the stern ramp. The cameras could be moved and also had zoom ability. Monitors were on the bridge (located at port side of the entrance to the chart room) and in the ECR above the instrument panel. The camera picture shown on the monitor could be changed to any other camera, either manually or automatically. The monitors on bridge and in ECR were showing the same picture. The main monitor with operating sticks was in the ECR, i.e. the bridge could not change to another camera nor operate the zoom. Later a further camera was installed at port side of the car deck, but it is unknown where and by whom the pictures were recorded.

- Officers and engineers had their accommodation directly in front of the superstructure overlooking the forecastle deck including the visor.

- The forepeak was more or less always full in order to keep the vessel on even keel. By means of tank No. 1 the trim of the vessel was adjusted depending on the number of trucks. The trim was mostly 0.5 - 1 m by the stern.

- After closing of ramps and visor the hydraulic pumps were always switched off, whereafter a rest pressure remained between cylinders and control lever which slowly decreased within the following 3-4 hours.

- Visor and ramps were exclusively operated by the chief officer and the boatswain.

- Sea watches were maintained at sea and in port.

- Safety rounds were made every 30 minutes on the car deck and below.

- The inside of the visor was only accessible via the entrance hatch on the forecastle part of the visor. There were no lamps installed inside the visor.